Recently, GEP bulky waste disposal production line complete equipment manufacturing, qualified testing, are sent to Chengdu. The smooth delivery of the equipment once again highlights the market reputation of GEP ECOTECH, and lays the leading position in the field of solid waste disposal.

Waste furniture, tables and chairs, sofas, mattresses, miscellaneous cabinets and other large pieces of domestic waste disposal is a difficult problem. Some citizens litter them everywhere, not only destroy environmental, but also encroach public place, there are safety risks. In order to ensure the cleanliness of the city and prevent the occurrence of safety accidents, it is particularly important to do a good job in the treatment of bulky waste in urban areas. As one of the 46 key cities of garbage classification in China, Chengdu has actively promoted the work of garbage classification, set up a bulky waste sorting center, introduced large waste disposal equipment, promoted the source utilization and further improved the level of garbage classification and treatment, and reduced the pressure of waste incineration.

With advanced technical advantages and rich project experience, GEP ECOTECH stands out from many suppliers of bulky waste disposal supplier, and successfully won the bid for Chengdu bulky waste disposal equipment purchase project.

GEP ECOTECH attaches great importance to the project cooperation. With our strong production capacity and efficient project team, we completed the delivery task in one month. It not only fulfilled the promise made by GEP with practical action, and also highlighted the quality of GEP ECOTECH and good contract keeping promise, which greatly improved the trust and satisfaction of customers. Prove that GEP ECOTECH is a trusted partner.

After the equipment has arrived at the project site, the after-sales engineer of GEP ECOTECH go to Chengdu installation site at the first time to guide and installation work which helped the customer greatly shorten the installation and debugging period, and provide the customer with an early acceptance.

How to dispose bulky waste?

Bulky waste generating units and individuals put bulky waste into designated stacking places. The person responsible for the management of bulky waste shall hand over the waste to the city appearance and environmental hygiene operation service unit for clearance and transportation, and centralize and standardize the transportation to the bulky waste sorting center.

The bulky waste are centrally disposed by the waste sorting center, repair the waste which can be used again, disassemble the no use waste and recycle some parts to be reused, while the non-recyclable parts are dealt with separately.

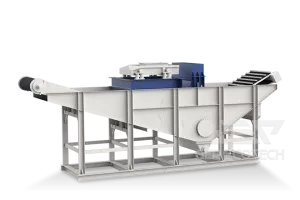

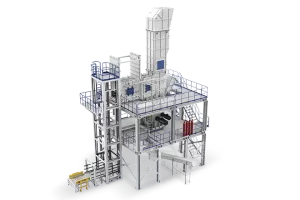

GEP bulky waste disposal production line mainly adopts the process of "crushing and sorting", which converts the large waste into reusable resources after crushing and capacity reduction and sorting. The production line is composed of transmission system, crushing system, magnetic separation system, intelligent monitoring system and intelligent dust reduction system, which makes large waste into treasure, improves recovery utilization rate, and truly realizes Chengdu large waste reduction, resource utilization and innocuous disposal.

Dozens of seconds to "eat" a large piece of waste

Bulky waste are sent to the conveyor belt to enter to the double shaft shredder, the shredder use two relatively rotating cutting shafts to shear each other, and the tearing principle breaks the material. Large pieces of garbage are quickly cut and shredded into small pieces, and the material is then transported to a magnetic separator after shredding. Under magnetic force, metal objects such as nails, wire, iron sheet will be automatically sorted out for centralized recycling and reuse. The rest of the material are sent to the transport truck, waiting for the next processing process.

In the whole production process, the operator can monitor the shredding and sorting process in real time through GEP GI intelligent monitoring system, which can effectively reduce the equipment operation failure rate and maintenance time, reduce the maintenance and operation cost, and greatly improve the operation efficiency of the production line. The production line adopts the closed design in the shredding and blanking area and is equipped with intelligent pulse dust removal system which control the dust to improve the workshop environment.