All the time, the waste tire is known as Black Pollution, it has gradually become a major problem in the field of global environment protection. The management of waste tire is urgent. Pyrolysis technology can realize the recovery of resources and the full reuse of valuable products. It is the most valuable new technology and development direction for waste tire disposal.

According to research, 1 ton waste tire (rubber) can produce about 0.35 ton carbon black, 0.12 ton steel wire and some combustible gases through thermal cracking. Compared with the disposal methods of waste accumulation, landfill, combustion and incineration, thermal cracking technology is more safe and environmental protection, energy saving, good comprehensive economy, in line with the development trend of the times.

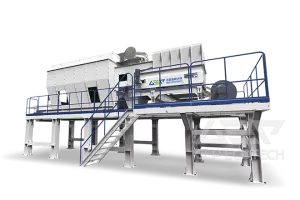

Enter the site of GEP Southeast Asia cracking and disposal site of waste tire, we can see that GEP disposal line has been basically assembled, the workers are busy debugging and optimizing. After being shredded and sorted by the tire disposal line, the waste tires will directly enter the tire cracking and refining equipment, and the waste tires will be decomposed into steel wire, carbon black and fuel oil to solve the black pollution, which not only creates green economic benefits, but also promotes the local environmental protection construction process!

Southeast Asia waste tire disposal project mainly shred car tire and truck tire. The owner purchases GEP waste tire disposal production line, which is used for tire cracking, refining and power generation shredding pretreatment. Before the thermal cracking treatment, waste tire needs to be shredded and steel wire separated to achieve the purpose of shredding, volume reduction and reducing transportation cost. The waste tire will be shredded and steel wire separated through the GEP tire disposal line, and then it will be turned into rubber block and sent to the cracking equipment.

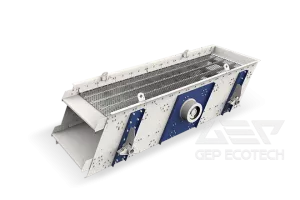

This production line is composed of tire bead wire pulling machine, feeding chain plate conveyor, double-shaft shearing shredder, trommel screen and discharging belt conveyor. The production line adopts the structure design of the combination of the double-shaft shearing shredder and the trommel screen, which not only makes the output and the discharge size meet the requirements, but also meets the planning and construction needs of the customer's tire disposal production and operation.

Shredding pretreatment process of waste tire:

After the steel wire is taken out by the steel wire pulling machine, the waste tires are transported to the double-shaft shearing shredder chamber by chain plate conveyor. The rotor in the shredding chamber is driven by the motor and reducer, the shredder adopts low speed and large torque to shred the tires into pieces. The outer side of the equipment is designed with a ring-shaped trommel screen. The rubber block cut into small pieces and fall on trommel screen. The rubber blocks smaller than the mesh diameter fall on the output equipment for the next process. The rubber blocks larger than the mesh diameter return to the shredder chamber for secondary shredding. The shredded rubber block is discharged from the belt conveyor, and the final discharge is directly sent to the cracking and refining equipment.

Pyrolysis technology of waste tire

The waste tire was shredded and sent to the cracking furnace for catalytic heating, so that it could be cracked into cracking gas and cracking distillate oil, and at the same time, carbon black was formed by reaction. Gasoline, diesel and heavy oil can be obtained by further fractionation of cracked distillate. The solid waste produced in the process is carbon black, which will reach the industrial raw material standard after processing. The waste gas is non condensable combustible gas. Through recovery and full combustion, it will provide heat for the whole production process and generate electricity, which not only eliminates waste gas pollution, but also saves a lot of fuel. The whole cracking process is carried out in a closed environment to minimize the leakage of pollutants.

GEP tire disposal line is customized according to the actual needs of customers, and the discharged size can be controlled. The whole production line is equipped with a unique GI intelligent detection system, which can realize automatic and intelligent production. Only one or two operators are needed. The crushing efficiency is high, the production line is highly automated and intelligent control, the whole processing process is energy-saving, efficient, safe and environmental protection. At present, with a number of scientific and technological patents to support the optimization of product transformation and upgrading, GEP has successively designed one-stop solid waste disposal station solutions for many domestic and foreign partners, which has won high praise from customers.

In the future, GEP will always adhere to the “Going out” and respond to the “the Silk Road Economic Belt and the 21st-Century Maritime Silk Road” initiative actively, accelerate abroad layout, promote the competitiveness of GEP solid waste disposal products and enhance the overseas market development, promote the transformation of Made in China to Made with Wisdom, and provide a strong driving force for the sustainable development of the company.