| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| GF13 | 1-6 | 50-150 | 3200×2000×3000 |

| GF15 | 2-10 | 4000×2000×3000 | |

| GF18 | 3-15 | 4500×2200×3200 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

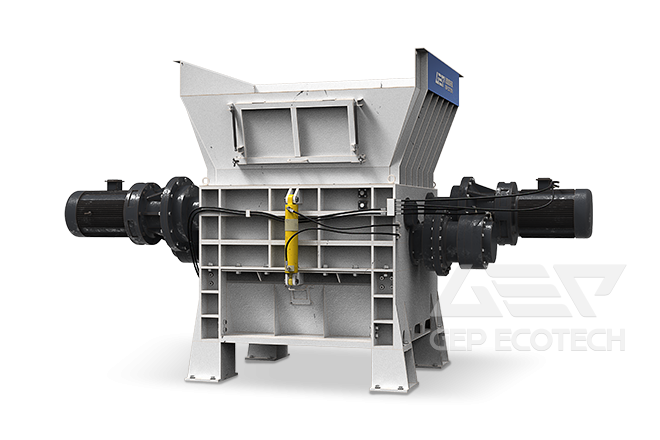

Four-Shaft shredder is a multi-purpose shredder. It has the same working principle as two-shaft shredder. GF Series four-shaft shredder can control the final material size by equipping a screen at the outlet. Four-shaft fine shredder provides greater shearing force than two-shaft shredder, it can handle all kinds of toughness, ductility of waste materials and obtain consistent shape and size.

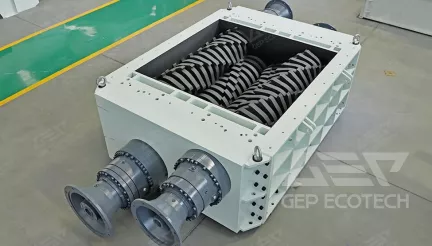

In general, four-shaft shredders are used for more difficult tasks, such as reducing large volumes of material to a small and uniform size in a single pass, while maintaining good throughput. The function of the two cutters above the four-shaft shredder is to clean the shafts below and at the same time provide a certain amount of shearing force.

The GF Series four-shaft shredder has four sets of shear rolls with different tool configurations to match each other. Once inside the shredding chamber, the material is shredded into small pieces by the tearing and shearing action of the blades on the four sets of rolls. The size of the output material is controlled by the screen. After the material is cut once, the material with a smaller particle size than the hole of the screen is discharged from the lower part of the box under the action of gravity and squeezing pressure, while the material with a larger size than the hole of the screen is guided by the main cutters and the secondary cutters to return to the inner surface of the screen for the second cutting, and so on until the material can be discharged from the hole of the screen.

GEP Ecotech offers a high performance heavy duty four-shaft shredder for large applications. It uses a high horsepower motor in combination with a large high speed ratio reducer, making it easy to cope with the disposal of bulky waste, car shells, non-ferrous metals, various industrial and hazardous waste.

Four sets of shearing cutter rollers with high efficiency cooperation to reduce ineffective gripping, reversing and idling time and high efficiency.

Intelligent monitoring system for automatic memory, data analysis, fault prediction, alarm stop and intelligent maintenance.

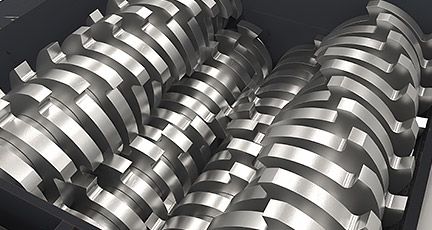

Cutters with high wear resistance, moderate toughness, strong interchangeability and long service life.

High strength spindle refined by multiple processes, high mechanical strength, high fatigue and impact resistance and long life.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| GF13 | 1-6 | 50-150 | 3200×2000×3000 |

| GF15 | 2-10 | 4000×2000×3000 | |

| GF18 | 3-15 | 4500×2200×3200 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

Waste Tire Shredding & Recycling System

Construction & Demolition Waste Disposal System

Municipal Solid Waste Disposal System

Refuse-Derived Fuel & Solid Recovered Fuel System

Hazardous Waste Disposal System

Pre-Shredding System for Biomass Power Plant

Industrial & Commercial Solid Waste Disposal System

Send your inquiry for further information.

Find More Ways, Contact Us Today!

WhatsApp

WhatsApp

WeChat

WeChat