For a long time, waste tires have gradually become a major problem in the field of global environmental protection, known as "black pollution", and its treatment is urgent. Waste tire recycling technology is the most valuable emerging technology and development direction of waste tire disposal, which can realize the recovery of resources and the full reuse of valuable products.

Waste tire recycling technology

It is reported that about 0.35 tons of carbon black, 0.45 tons of waste rubber oil, 0.12 tons of steel wire and some combustible gases can be produced from 1 ton of waste tire (rubber) by thermal cracking. Compared with the disposal methods of waste accumulation, landfill, combustion and incineration, pyrolysis technology is more safe and environmental protection, energy saving and good comprehensive economy, which is in line with the development trend of the times.

GEP Waste tire recycling line in Southeast Asia

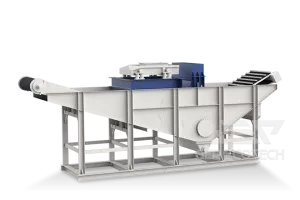

The waste tire recycling project in Southeast Asia mainly process car tires and truck tires. Customers purchase GEP waste tire recycling line, which is mainly used for shredding pretreatment of tire cracking, oil refining and power generation. Before pyrolysis of waste tires, it is necessary to crush and separate steel wires to achieve the purpose of crushing and reducing transportation cost. Waste tires will be broken and separated from steel wires by GEP tire recycling line, and then transformed into rubber blocks and sent to cracking equipment.