GEP Ecotech offers a complete line of industrial shredding equipment to handle various waste recycling or reduction requirement. All equipment is manufactured in Henan under strict quality control. The experience of design and the use of Canada and China cooperate technologies in the creation of our shredders makes it possible to offer high-quality and reliable equipment for work in various conditions. Our specialists provide technical support for the project from the moment of ordering to commissioning.

GEP Ecotech Industrial Shredder Ranges

In our catalog you can choose shredders of various capacities and configurations for shredding solid wastes. All shredder models have different performance characteristics, dimensions of the loading chamber and other indicators. When choosing a shredder, it is necessary to build on the type of the processed raw materials. Based on its quality properties, the selection of equipment is carried out.

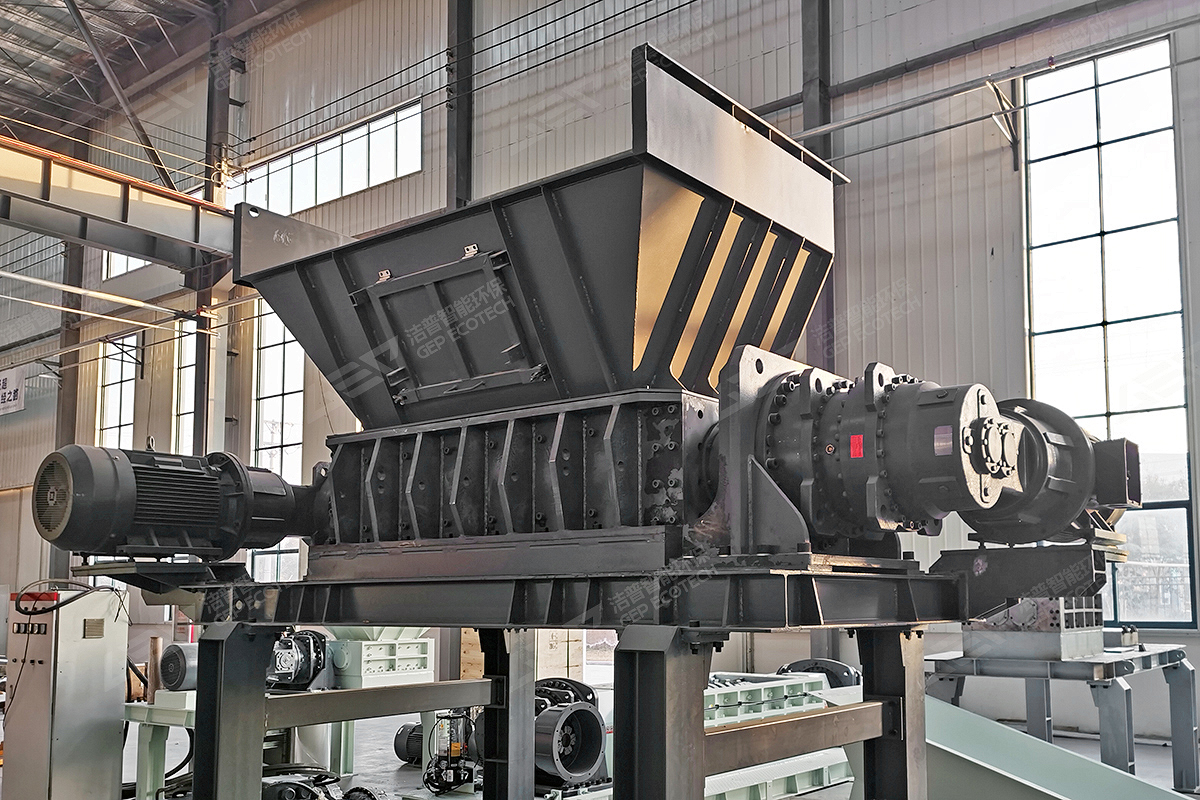

Double-Shaft Shredder

Double-shaft industrial shredder suitable for shredding various materials.Thanks to two independent drives, the double-shaft shredder has increased productivity and greater load resistance. The cutting knives are mounted on 2 hex shafts that rotate at different speeds for more efficient material chopping. The shredder is controlled by a central control system, which controls the operation of the electric motors, and also provides a reverse in case of material jam.

Single-Shaft Shredder

Single-shaft shredder is used for fine process of waste. Its qualitative difference from the two-shaft shredder is the shredding of raw materials into smaller and more homogeneous size. The single-shaft shredder is equipped with a hydraulic pusher that propels the material to the rotating shaft, and by passing the raw material through the mesh, the shredded product is obtained at the exit. Single-shaft shredders are preferred in situations where shredding to a certain size is required. Single-shaft shredders are perfect for working with non-ferrous scrap, plastic, aluminum, radiators, aluminum cans, cables.

Four-Shaft Shredder

Four-Shaft Shredder is the most powerful Industrial shredder. It is equipped with four rotating shafts that grip, pull and shred various types of waste. Due to their high power and productivity, the four-rotor shredders are suitable for the primary processing of bulky waste: car tires and bumpers, old furniture, plastic and metal drums, pallets and other bulky and complex materials. Despite its power, the four-shaft shredder is simple and reliable in operation.

Customized Equipment and Solutions

Although we have several fixed shredder product series, but there are no customers have the same needs, which means that we have advanced customized production capabilities. Whether you need to dispose of any type of solid waste for volume reduction, recycling, landfill or other purposes, we can provide customized solutions and equipment.