Domestic garbage has a large amount of production, complex composition, contains a large amount of organic matter, and is easy to breed a large number of bacteria and emits malodor. Its main components include coal ash, kitchen slag, peel, plastic, fallen leaves, fabric, wood, glass, ceramics, leather and paper, as well as a small amount of batteries, medicinal packaging materials, aluminum foil, SP composite film / bag, rubber and so on.

The treatment of domestic garbage has become the trap of the current era, the question of the environment? It is the wish of every Chinese to directly look at and sort out the sorting and sorting of domestic garbage, and to cure the existing domestic garbage. A historical responsibility carried by green business people. The types of municipal solid waste are complicated, and the piles are messy and piled up. The hardness is different, the distribution is scattered, and it is inconvenient to handle them uniformly. Jiepu intelligent environmental protection adopts new domestic garbage disposal technology, independently developed a mobile garbage crushing station, turning urban domestic garbage into waste, realizing the reduction, resource and harmless disposal of domestic garbage.

Why is it called "station" rather than "machine"?

It is because the mobile crushing station has developed into a highly integrated equipment that integrates the process of receiving, crushing, and conveying.

The chassis of GW series mobile solid waste crushing station is higher, the width of the car body is smaller than that of the operating semi-trailer, and the weight of the car body is lighter. The modules are loosely arranged in space, and the external belt conveyors of most products are almost untouchable when moving, and the safety cannot be completely guaranteed.

The tire-type mobile solid waste crushing station can easily realize free walking, in-situ steering, transportation, climbing, etc., but generally does not have a travel drive system, and the degree of automation is not high. It is not a mobile crushing station in foreign product classification because It is necessary to move under the traction of the truck head. Because of the tire walking mode, it is convenient to transport during long-distance transitions, which is convenient for ordinary roads and does not damage the road surface.

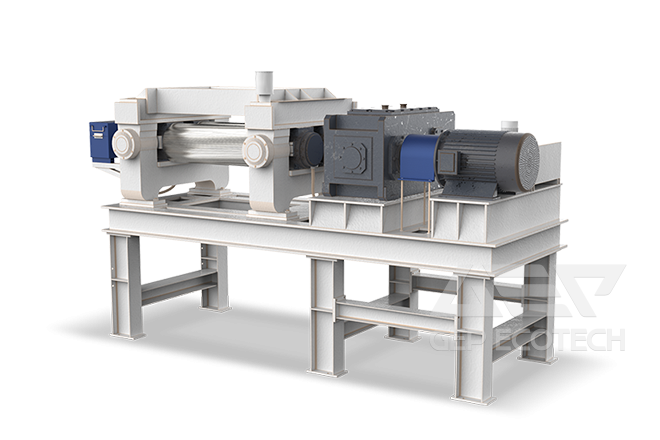

Based on advanced crushing technology in North America, GW series mobile solid waste crushing plant integrates process equipment such as mobile chassis, feeding, crushing, conveying and magnetic separation. It is an ideal equipment for dispersing garbage in the city and suburbs. The design concept fully considers the crushing requirements of various materials, eliminates the impact of crushing sites, environment, foundation, disposal volume, electricity and other factors on production, and provides customers with simple, efficient, stable and low operating cost crushing equipment; GW The series mobile solid waste crushing station has a built-in diesel engine, which can be produced without external power supply. It has a mobile chassis and is convenient and quick to move. The overall hydraulic drive is efficient and stable.

At work, the GW series mobile solid waste crushing station needs to increase the stability of the whole equipment through the hydraulic support legs provided under the frame. There are certain requirements for the foundation of the site. When the rock mass of the site is strong, the bearing capacity is large, and there is no equipment during construction. In the case of sinking, the working efficiency of the equipment is high. When the equipment is slightly poor in construction, the working efficiency will be reduced. Therefore, the tire type mobile crushing station has certain requirements for the work site. Even with all-terrain operations, the equipment and equipment need to be adjusted and prepared accordingly, and the preparation work is more.

The GW series mobile solid waste crushing station has the following characteristics:

1, GI intelligent patent technology, remote monitoring and diagnosis

Real-time control and monitoring of the entire production process using GI intelligent technology, real-time online operation status monitoring and centralized control, timely feedback of operational data to the general control center, remote diagnostic control of the production line through mobile phone APP or computer, automatic memory and data analysis , fault prediction, alarm shutdown, linkage control, intelligent maintenance and other functions, forming an effective early warning mechanism, effectively reducing equipment failure rate and maintenance time, reducing maintenance and operating costs, and greatly improving the operating efficiency of the production line.

2, flexible, easy to transfer

The mobile solid waste crushing station has a short transport length and a small turning radius, and can be flexibly driven in ordinary roads and working areas. The transition is convenient and fast, and can be quickly transferred between garbage disposal points.

3, compact structure, small footprint

The mobile solid waste crushing station integrates the mobile chassis, diesel engine, feeding, crushing, conveying, magnetic separation and other process equipments. The structure is compact, the overall footprint is small, no special installation foundation is needed, and the hydraulic support can be started. .

4, a variety of configurations, diverse combinations

According to the needs of users, the mobile solid waste crushing station can be equipped with different types of crushing equipments of coarse, medium and fine. At the same time, it can be equipped with conveying and magnetic sorting equipment. It can work independently or in combination with other equipment. The working mode can be variously selected.

5, precision processing technology, high quality parts

The mechanical strength and processing precision of the core crushing equipment prolong the service life of the equipment; the tool material is imported high-alloy steel, which is processed by special process to ensure the wear resistance and impact resistance of the tool; bearing, motor, reducer, electronic components All of them are internationally renowned brands, ensuring the overall quality of the equipment.

6, the overall hydraulic drive, efficient and stable operation

It is equipped with imported high-power hydraulic motor and low-speed hydraulic variable pump, and has powerful power output to ensure efficient and stable operation.

7, high-end design

The overall design combines practicality and industrial beauty to show a calm and generous temperament. The tire mobile structure has high strength, low grounding ratio, good passability, and can adapt to complex geographical environments. The reasonable and compact space layout of the whole machine unit improves the flexibility of the station.