Biomass energy is an important part of renewable energy. In recent years, with the support of national policies, my country's biomass power generation industry has developed steadily. As of the first half of 2020, the country's biomass power generation installed capacity is about 25.2 million kilowatts, which has played an important role in building a clean, low-carbon, safe and efficient energy system.

Biomass power generation is one of the new energy sources with the most development and utilization potential, with good economic, ecological and social benefits. Straw can not only be used as a fuel to generate electricity, but the heat produced by burning also has the ability to centrally supply heat to surrounding enterprises, and at the same time, power generation can be used to supply power to the local area. The ash residue left after combustion can be comprehensively utilized to produce white carbon black as an industrial raw material, and it can also be provided to a nearby fertilizer plant as a raw material for agricultural fertilizer production, so as to finally form a biomass-electricity-heat-chemical industry chain.

Acceleration of innovation, GEP helps the reuse of biomass resources

Before the biomass is turned into heat and electricity, the straw needs to be crushed. The burning of straw after crushing will be more efficient and convenient. The crushing of biomass is an important link in the process of biomass cogeneration projects.

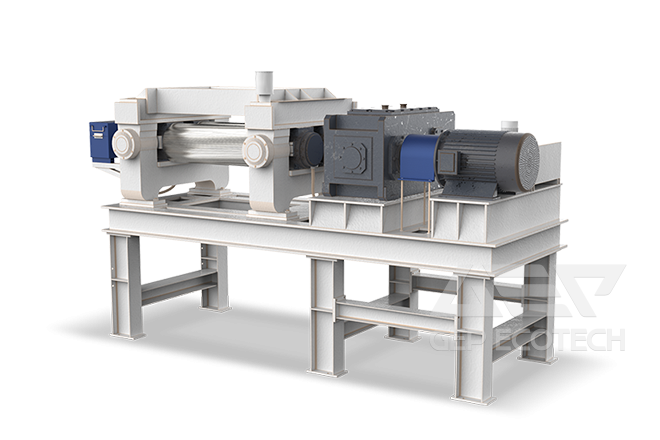

The GEP biomass fuel pre-crushing system is mainly composed of multiple double-shaft shearing crushers, metal chain conveyors, belt conveyors, GI intelligent monitoring systems and intelligent dust reduction systems. The disposal efficiency is high and the biomass fuel becomes easy to store, transport and supply on a large scale.

The metal chain conveyor or grabber feeds the biomass agricultural and forestry wastes into the crusher uniformly. The crusher crushes and disposes the materials through the working principle of shearing, tearing and squeezing. The crushed materials are separated by a magnetic separation device. The metal materials are selected and transported to the finished material area by the belt conveyor or transferred to the next disposal process. The entire production system can realize airtight transportation, negative pressure and dust reduction, and clean production.

Four advantages of the biomass fuel pre-crushing system:

Large capacity disposal design, high

The whole production line has large capacity and high crushing efficiency. The single machine capacity can reach 30-60t/h; the unique anti-winding device design can solve the problem of biomass baledisposal.

High-precision processing technology, strong

All key components of the production line are imported high-quality alloy forgings. After heat treatment, they have good wear resistance, high strength, and the service life is increased by 3 to 5 times; the integral tool box design, the frame structure is firm, and the strength is greater.

High-end component configuration, stable

The production line adopts imported bearings and multiple sealing technology, with high safety factor; advanced anti-loosening technology, avoiding equipment failures caused by loose bolts; equipped with high-end electrical components, with better controllability.

GI intelligent monitoring system, wonderful

GI intelligent monitoring system integrates data collection, data transmission, data storage, data analysis and other functions. Through real-time monitoring of the overall operating data and analysis of the production line, it can understand the operating status of the equipment in time, and realize the intelligent, digital and refined production line monitoring and management.

Deepen service and deliver the concept of customer first

GEP ECOTECH has a professional after-sales service team, and regular systematic technical training is carried out to better meet project needs. All service personnel have passed the qualification certification of senior after-sales service managers, have rich practical experience in equipment maintenance and repair, are familiar with the equipment structure, and can better guide the on-site equipment maintenance.

In order to provide the best after-sales service, GEP ECOTECH insists on the implementation of the "30+24+365" service standard: quickly respond to customer inquiries within 30 minutes and give answers to technical consultations; dispatch after-sales engineers within 24 hours to handle them; 365 days open all year round, accept service consultation requests.

Standing at the forefront of the times, shouldering the mission of the industry. GEP ECOTECH has always adhered to technology research and development and innovation, paying tribute to its original intentions, providing global users with a series of integrated solutions for intelligent solid waste disposal, serving many countries and regions around the world, and providing global users with high-quality products and professional after-sales services.