After the sharing of the bicycle boom, shared bicycle cemeteries appeared in many places, and used shared bicycles have become intractable urban garbage. According to estimates, by 2020, at least 10 million shared bicycles will be scrapped, occupying a large amount of public space and land resources, and generating at least 160,000 tons of solid waste. If these vehicles are recycled, they will reduce at least 110,000 tons of bauxite mining, reduce vegetation damage by 170,000 square meters, and reduce carbon emissions by 580,000 tons.

According to the person in charge of China's recycling, there are four main steps in the recycling of shared bicycles: picking, handling, dismantling, and recycling. Vehicles sharing the bicycle city's operation and maintenance personnel will reach the standard of scrapping, screening and unified placement. When the shared bicycle is judged to be a bad car or a scrap car, it will be sent to the recycling resource recycling factory. The scrapped bicycles are fully broken and sorted, and the metal parts become the raw materials for copper-iron and aluminum, and the garbage is used for incineration.

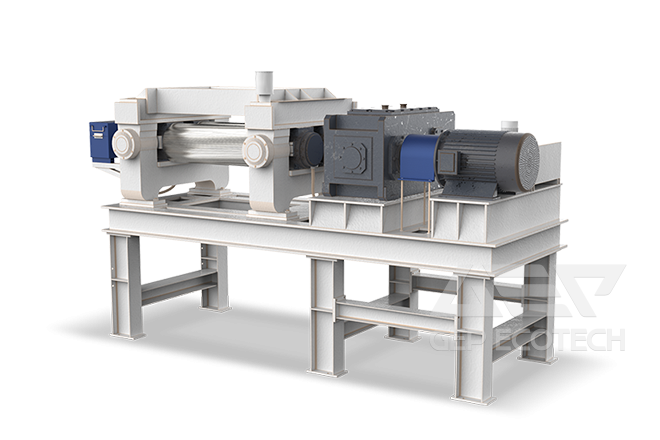

GEP ECOTECH GP series hydraulic rough crusher is one of the mainstream crushing equipment with high metal crushing production efficiency, and it is used in the first process of various solid waste crushing. The double-shaft coarse crusher is mainly composed of a main shaft, a blade, a middle comb plate, a box body, a power system and the like. The cutter roller is directly driven by a low-speed, high-torque dual hydraulic motor. The material is treated by cutting, tearing and pulling the material by the interaction between the movable knife and the middle comb. It has the characteristics of large crushing force, high output, low noise and good stability. It is often used in the crushing treatment of various solid wastes, domestic waste crushing treatment, garbage reduction and other fields; the material has wide applicability and high crushing efficiency.

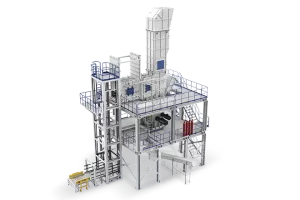

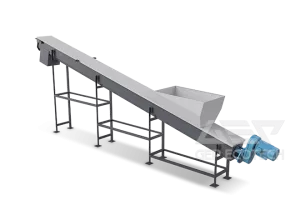

In order to improve the recycling of scrapped bicycles, GEP ECOTECH has developed a smart metal crushing and disposal production line, which integrates the functions of “crushing + sorting”. The production line is equipped with a GI intelligent monitoring system, and the entire process is an automated production process that reduces labor costs. The scrapped bicycles are sequentially put into a metal shredder and are automatically broken. After the crushing, magnetic separation is performed, the iron is sorted out, and then the aluminum eddy current is classified to separate the aluminum from other substances. Garbage will generate electricity at night, and the metal will become the raw material for copper, aluminum and iron. Basically, 99% can be recycled.

After the preliminary dismantling process of the GEP ECOTECH metal crushing and disposing production line, the scrapped bicycle was finally subdivided into iron, aluminum and plastic. After subdivision, the metal materials such as the main frame will be recycled to the metal ingots or metal products for recycling; aluminum is made into aluminum ingots, which can be used for high-end aluminum products, aluminum alloy doors and windows, ordinary aluminum products, etc. according to different grades; Body plastics are processed into plastic pellets for reuse, such as plastic washbasins, automotive interiors, etc.; for tires, cushions and other parts that cannot be completely decomposed, they will be scientifically harmless.

The scrap sharing of bicycles is not a real “urban waste”. After compression processing and crushing and separation, it has become the last value of renewable energy to achieve shared bicycles. Create a batch dismantling and recycling industry for shared bicycles, leading the shared bicycle industry into the era of circular economy.