As cars become more popular, discarded tires become an astonishing number. According to incomplete statistics, the annual production of used tires in China has increased sharply by 8% to 10%. By 2020, the output of used tires in China will reach 20 million tons, becoming a new “black pollution”.

The ecological environment is experiencing “black pollution”—the erosion of used tires: it will not be eliminated naturally and accumulated for decades, occupying a large amount of land, and is also prone to diseases and fires. The development of environmentally friendly equipment manufacturers that solve "black pollution" and develop a circular economy in the rubber industry is imperative.

The recycling of waste rubber refers to the physical morphological change of rubber for reuse, or the use of chemical addition to allow it to form other rubber products for reuse. Physical changes in the use of waste rubber can generally be used to make protective materials for trees, sports game materials, road paving, manufacturing soles, tire rebuilds, pasture fences or the manufacture of lifebuoys, etc., while chemical processing allows Waste rubber produces recycled rubber, rubber powder, rubber asphalt, etc. It can also be used in the non-rubber industry.

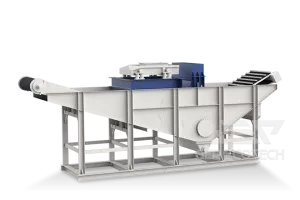

GFM series tire steel wire separator

GFM series tire steel wire separator is a kind of equipment developed by GEP ECOTECH for the current trend of recycling of used tires and based on market demand and practical experience. The performance of this equipment is stable, and the technical indicators meet the national standards. There is no secondary pollution in production, which can maximize the utilization rate of used tires and waste rubber.

The GFM series tire steel wire separator consists of a motor, a reducer, a rotating knife roll, a box, a frame, a screen, and a hydraulic auxiliary mechanism. The equipment pulverizes the used tire rubber block (50-100mm) after preliminary treatment into 15-30mm particles, and separates the steel wire and part of the fiber from the rubber during the pulverization process.

The working principle of GFM series tire steel wire separator:

The rubber block is shredded and sheared to a smaller particle size by rotating the trowel on the knife roll and the boring tool on the box to shear and crush the rubber block. At the same time, the steel wire and part of the fiber and the rubber are screened and separated during the process of crushing the rubber block. The bottom of the wire separator is equipped with a screen mesh, and the material smaller than the mesh hole will fall through the screen; the material larger than the mesh hole will remain in the crushing cavity and be broken again until it breaks down to the mesh hole. until.

Product advantages of GFM series tire steel wire separator

1.GI intelligent patent technology, remote monitoring and diagnosis

Real-time control and monitoring of the entire production process using GI intelligent technology, real-time online operation status monitoring and centralized control, timely feedback of operational data to the general control center, remote diagnostic control of the production line through mobile phone APP or computer, automatic memory and data analysis , fault prediction, alarm shutdown, linkage control, intelligent maintenance and other functions, forming an effective early warning mechanism, effectively reducing equipment failure rate and maintenance time, reducing maintenance and operating costs, and greatly improving the operating efficiency of the production line.

2. Stable and reliable operation

The reducer is used to drive the knife roll, which runs smoothly and has low vibration.

3. Unique cabinet design

The cabinet is processed by a high-precision CNC machining center to ensure smooth operation of the equipment for a long time and high load, and to extend the service life of the transmission components.

4. The whole machine has strong wear resistance

The wear-resistant steel plate is easy to wear, which greatly improves the overall wear resistance and effectively reduces the maintenance period and maintenance cost of the equipment.

5. The spindle has strong impact resistance

The main shaft is made of high-strength alloy steel, and the whole process is tempered to ensure long-term high-load operation.

6. Easy tool change

The cutters can be disassembled and installed independently, and can be quickly disassembled in a short time, which improves the continuity of production; the fixed cutter can be repeatedly repaired and used, with good interchangeability and long service life.

7. Blade clearance can be adjusted

The blade gap can be adjusted according to the type and thickness of the material to achieve the best crushing effect.

8. Humanized design

The hinged connection of the upper and lower cabinets is opened or closed by hydraulic pressure, which greatly facilitates the inspection and maintenance of the knife roller; the screen is hydraulically driven to open or close, which can be quickly replaced and maintained.

Tire rubber is more valuable than other rubbers because of its unique wear resistance, aging resistance, water resistance, shock absorption and other characteristics. Therefore, most of the treatment of used tires is now a physical crushing method, which becomes a useful rubber after processing. Granules, rubber powder, steel wire and fiber. These rubbers are used in a very large area and can be used for roadbed construction, rubber track construction, and various rubber products. In addition, the rubber block after the crushing treatment can also be used for refining, because the tire contains a large amount of elements such as sulfur, carbon, nitrogen, etc., after high temperature cracking, and then cooled, and distilled to extract gasoline.