| Model | Capacity(t/h) | Power(kW) | Output size(mm) |

| GPT | 1-4 | 110-160 | 10-30 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

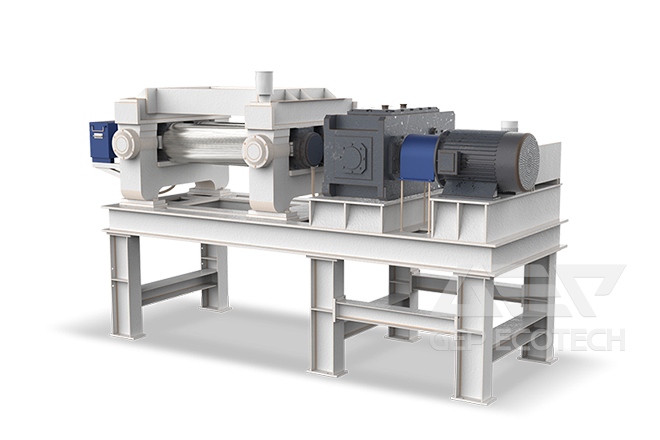

The GPT rubber grinder is a device that further shreds and grinds the roughly shredded tire rubber blocks at room temperature, with the functions of fine shredding, and separating steel wire and rubber. The shredding effect of this equipment on steel wire block material is relatively ideal, with a one-time discharge particle size of 10-30 mesh. After screening, transportation, and magnetic separation, it can reach about 99% pure rubber particles and powder.

The rubber grinder is mainly used for the shredding of waste rubber and the shredding of recycled rubber. It is composed of the body, transmission system, safety device, temperature regulating device, lubrication system, electrical system, etc. It effectively solves the problems of low efficiency, low output, and narrow range of applicable rubber particles in traditional rubber grinders. It is a new type of product with high production efficiency and wide application range.

The rubber grinder adopts a grinding mechanism of rotary grinding. During operation, the material enters the grinder through the feeding port, and the front and rear rollers are driven by electric motors and deceleration devices. At a certain speed ratio, they rotate in opposite directions to grind the material into a certain number of rubber particles or powder.

The roller is made of Vanadium Titanium alloy chilled cast iron, which is hard and wear-resistant; The rear roller is a groove roller, with an inner cavity machined to ensure uniform temperature on the roller surface.

Equipped with an overload protection device to protect the main components from damage due to overload, with stable and reliable performance.

Equipped with emergency braking. When an emergency accident occurs, pull the pull rod to immediately brake the equipment, ensuring safety and reliability.

The transmission system adopts NGW hard tooth planetary reducer or herringbone gear reducer, which is compact in structure, low in noise, and high in efficiency.

Adopting an integral or split base for easy installation.

| Model | Capacity(t/h) | Power(kW) | Output size(mm) |

| GPT | 1-4 | 110-160 | 10-30 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

Waste Tire Shredding & Recycling System

Construction & Demolition Waste Disposal System

Municipal Solid Waste Disposal System

Refuse-Derived Fuel & Solid Recovered Fuel System

Hazardous Waste Disposal System

Pre-Shredding System for Biomass Power Plant

Industrial & Commercial Solid Waste Disposal System

Send your inquiry for further information.

Find More Ways, Contact Us Today!

WhatsApp

WhatsApp

WeChat

WeChat