1. Project Overview

In October, European customers visited GEP factory and formally signed cooperation with GEP on the production line of biomass fuel shredding and disposal. On November 14th, the kick-off meeting of fuel shredding treatment system of GEP&NNBP 25MW biopower plant project was successfully held in the conference room of Zhengzhou GEP Ecotech Co. Ltd.

As the fourth largest energy source, biomass has become one of the most promising new energy sources because of its renewable and zero carbon emissions. NNBP 25MW biopower plant project uses sugarcane leaves as burning materials for biomass power generation, turning waste sugarcane leaves into treasures, which not only protects the surrounding environment, but also generates considerable economic benefits, and also provides safe and reliable electricity for the local area. GEP is mainly responsible for the two projects to provide solutions for biomass fuel shredding and the manufacturing of equipment for the whole disposal production line, to ensure that the shredding and disposal production line meets the customer's shredding needs.

2. Biomass Fuel

Biomass pellet, also known as biomass briquette fuel, is a new clean fuel which can be burned directly after shredding, using agricultural and forestry wastes (such as straw, sawdust, bagasse, rice chaff) as materials. Compared with traditional fuels such as coal and liquefied gas, it has not only economic advantages, but also environmental benefits, and perfectly meets the needs of sustainable development.

Transportation expenses accounts for the largest proportion of agricultural straw fuel cost. The main reason is that biomass fuel has the characteristics of large volume and light weight. Many biomass power plants have the problem of fuel storage and transportation. After shredding, biomass fuels can be transported easily, combustion efficiency can be improved and air pollution can be reduced.

3. Biomass Fuel Shredding and Disposal Production Line

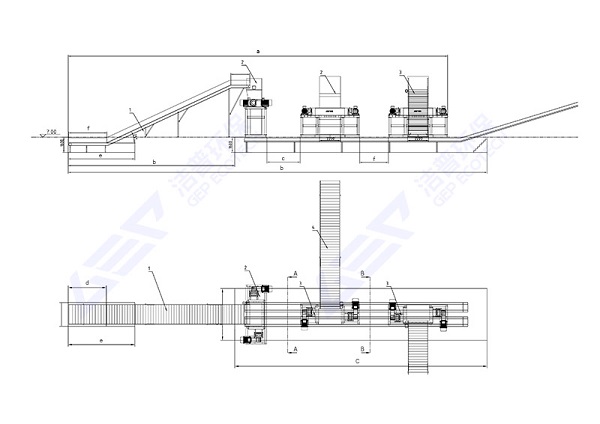

According to the characteristics of biomass fuels, GEP has independently designed and developed a production line for shredding and disposal of biomass fuels. The overall product line structure is specially designed according to the customer needs and meets the actual production needs of customer. In addition, GEP biomass shredding system adopts chain plate intelligent feeding, which can automatically adjust the feeding speed according to the load of the main motor. It is an ideal preferred equipment for biomass power plants run at full load without no-load operation, make feeding more smoothly and greatly improve the yield. The biomass fuel shredding and disposal is mainly composed of three double-axis shear crushers and multiple chain conveyors, which can crush 40 tons of materials per hour and make it easy to store, transport and supply on a large scale with the size of less than 100 mm after crushing.

4.How does the biomass fuel crushing production line work?

Shredding and Disposal Technology of Biomass Fuel:

Biomass materials are stacked in sequence along the feeding direction of the chain

shredder, they are pushed into the shredder by the upper eccentric swage for shredding treatment. When the shredder is running, the intelligent control system temporarily suspends the operation of the chain conveyor and temporarily stores some raw materials on the conveyor to ensure the continuous and sufficient supply of raw materials in turn, thus avoiding the equipment failure caused by the accumulation of biomass raw materials in the shredder silo. The shredded biomass raw materials are concentrated on a discharging conveyor, and the output biomass fuel is to be processed in the next step.

5. Advantages of Biomass Fuel Crushing Production Line

(1)Intelligent Control

GEP intelligent patented technology of production line realizes automatic lubrication, intelligent detection and abnormal alarm. PLC touch screen control cabinet or mobile client can real-time monitor the operation status of equipment with high safety factor. The system fully controls the feeding speed of chain plate conveyor, avoids material accumulation and blockage of shredding chamber, and it

(2)Credible quality

Imported high-quality alloy forgings are used in all key parts of the production line. After heat treatment, the product has good wear resistance, high strength and The service life is increased by 3-5 times compared with domestic high manganese steel part. Integral shredding chamber design makes the machine structure stronger and more stable.

(3)Stable performance

The production line adopts imported bearings and multiple seals technology with high safety factor, advanced anti-loosening technology avoids equipment failure caused by bolt loosening, and equipped with high-end electrical components with good control.

(4)Energy-efficient

The equipment of the production line has good comprehensive performance. It has unique effect on straw shredded, bagasse and other biomass raw materials. It has a wide range of applications. The shock absorption device is designed with stable operation and low noise.

At present, GEP intelligent solid waste shredding equipment has been widely recognized in the domestic and foreign markets. It not only radiates the whole country with Henan as the center, but also emerges in the international market and wins high praise. It is exported to many countries in the world, such as Norway and Malaysia. GEP intelligent solid waste equipment is stepping into the overseas market step by step to realize the leap of enterprise intelligence, brand internationalization and high quality, so that Chinese manufacturing can go to the world, and display the strong strength of Chinese manufacturing.