Since the completion of bulky waste disposal project in Shuangliu District of Chengdu in November 2019, it has been put into operation for more than half a year, with a daily treatment capacity of 50 tons.

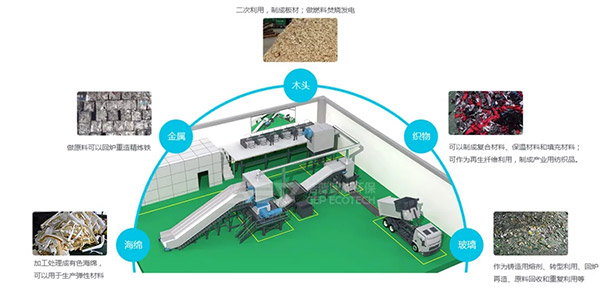

Due to the low recycling value, high transportation cost and inconvenient dismantling on site, bulk waste such as old sofa, old mattress and old wardrobe have become a difficult problem in waste classification and treatment. Bulky waste is mainly composed of metal, wood, sponge, leather and other components. After classified treatment, it has high recycling value. Therefore, volume reduction, crushing and resource utilization are the only way to deal with bulky waste.

With the development of waste classification treatment in Chengdu, the terminal treatment facilities for bulky waste are completed and put into use, and the front-end collection sites are gradually spread out. These bulky wastes have a more appropriate treatment method -- through the community collection site unified collection, and then transported to the treatment site for crushing and reducing capacity, so as to realize waste reduction, recycling and harmless treatment.

Walking into the project site, we can see that the bulky waste is sent to the chain plate conveyor in batches and crushed by the double shaft shear shredder. After crushing, the materials are transported to the magnetic separator. Under the action of magnetic force, metal objects such as iron nails, iron wire and iron sheet will be automatically sorted out for centralized recycling. After crushing, the materials are transported to the magnetic separator. Under the action of magnetic force, metal objects such as iron nails, iron wire and iron sheet will be automatically sorted out for centralized recycling. The rest of the materials are sent to the transfer vehicle, into the compression transfer and incineration power generation system, finally realize the bulky waste recycling.

When the bulky waste disposal system is running, there is almost no noise at the disposal site. The secret is a black big box - professional noise reduction room. The noise reduction room can effectively reduce equipment noise, ensure safe operation and solve the problem of NIMBY. In addition, the bulky waste disposal site is equipped with GEP intelligent dust removal system, and the gas and dust generated during waste crushing will be subject to pulse dust collector , so as to ensure the site is clean, safe and efficient.

Chengdu bulky waste disposal project chose GEP, this shredding system adopts crushing+sorting process to transform the bulky waste into reusable resources after crushing and reducing the volume. The production line is composed of conveying system, crushing system, magnetic separation system, intelligent monitoring system and intelligent dust suppression system. Mechanical crushing replaces manual disassembly, which greatly improves work efficiency, improves working condition and reduces potential safety hazards caused by manual disassembly.

The intelligent technology is closely integrated with the equipment manufacturing process. GEP GI intelligent monitoring system opens up the data "island" and builds a unified, intelligent and efficient smart brain of solid waste disposal equipment. The system creates fine monitoring and management realizes information transmission network, personalized data report, intelligent data analysis, visualization of production process control, real-time abnormal alarm, scientific production management and decision-making, helps users to accurately control the operation status of equipment in real time, greatly improves the operation efficiency of the production line and reduces the operation cost.

The production line can complete the crushing and volume reduction of a steel mattress in a few seconds, the daily processing capacity is about 20 to 50 tons. After bulky waste enter the workshop, then transport to the hopper of double-shaft shredder. After crushing, the recyclable metals are recycled by the magnetic separator, the remaining combustible materials are transported to the waste transfer station for compression treatment, and then transported to the power plant by special transport vehicles for incineration and power generation, so as to realize waste transformation for treasure.

The recycling and reuse of bulky waste will help to build a low-cost, high-efficiency resource-saving and environment-friendly society. After Chengdu bulky waste disposal project was officially put into operation, the waste sofa, mattress, furniture and other bulky waste have a new home, effectively solve the problem of bulky waste treatment, promote the bulky classification work of Chengdu to a great step forward.