| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| GSD12 | 1-6 | 30-120 | 3000×2800×3000 |

| GSD15 | 3-15 | 3600×2800×3000 | |

| GSD20 | 8-25 | 4200×3000×3200 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

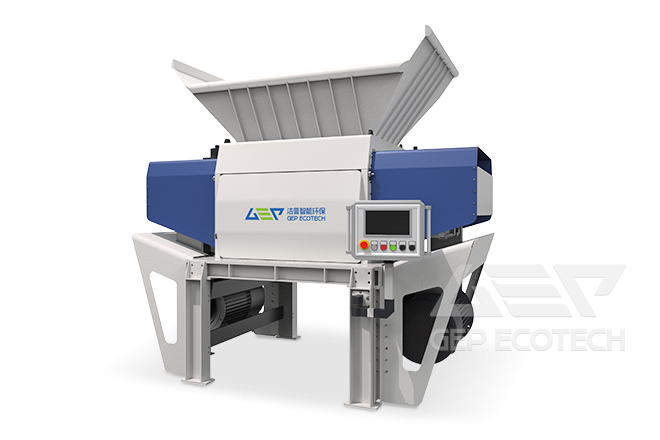

GSD is a powerful high-standard fine shredder that can quickly shred materials to the required shape and size. GSD uses dual rotors to shred materials, which is more efficient and has a larger production capacity.

The GSD series double rotor fine shredder is designed to cope with the more complex and severe task of fine shredding of waste. It can handle a variety of large volume solid raw materials such as rolls of plastic, bundles of waste paper, piles of fabric and so on. The two rotors of the shredder are independently driven and turn in opposite directions, feeding each other for multiple shredding and effectively improving shredding efficiency.

The GSD series double rotor fine shredder is an evolution of the single shaft shredder, with a symmetrical double shaft design. The material falls naturally into the shredding area through the feed hopper and each chip cutter shaft can be fed automatically at an even speed without the need for a pushing device. The cutter base and cutters are bolted to the main shaft and are of a detachable design to ensure a balanced spindle, low vibration, low noise, high efficiency, uniform discharge and controlled size, suitable for the shredding and disposal of a variety of large, soft and hard materials.

The motor drives the cutter shaft to drive the rapid rotation of the cutter. The cutters on the shaft and the fixed cutters cooperate to shear and tear the material for shredding, the unqualified material is brought back to the shredding area by the cutters for further shredding, the material reaching the size of the discharge falls from the screen to achieve the purpose of shredding. The size of the cutters and the size of the screen holes are selected according to the user's requirements.

Independent drive of double rotors, mutual feeding, multiple shredding, high shredding efficiency.

Integrated design of discharge screen and access door, hydraulic one-touch opening, easy maintenance.

Cutters are bolted to the cutter base, which is welded to the rotor, easy to change the cutters.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| GSD12 | 1-6 | 30-120 | 3000×2800×3000 |

| GSD15 | 3-15 | 3600×2800×3000 | |

| GSD20 | 8-25 | 4200×3000×3200 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

Construction & Demolition Waste Disposal System

Municipal Solid Waste Disposal System

Waste Tire Shredding & Recycling System

Refuse-Derived Fuel & Solid Recovered Fuel System

Hazardous Waste Disposal System

Pre-Shredding System for Biomass Power Plant

Industrial & Commercial Solid Waste Disposal System

Send your inquiry for further information.

Find More Ways, Contact Us Today!

WhatsApp

WhatsApp

WeChat

WeChat