With the continuous tackling of key technologies and the increase of environmental protection, the comprehensive utilization industry of waste tires has gradually changed the pattern of scattered, small, dirty and disordered. New tire disposal technology has become one of the important directions of comprehensive utilization of waste tires.

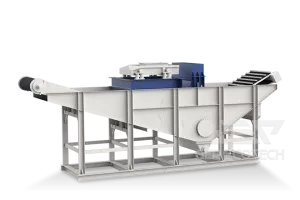

GEP waste tire recycling and disposal system uses normal temperature physical method to shred, separate steel wire, crush, fiber separation and other disposal of waste tires, making waste tires become the "black gold" of renewable resources. The production line runs at normal temperature without any chemical additives and will not cause secondary pollution to the environment.

After crushing and steel wire separation, these tires will become knuckle sized rubber particles, which will be sent to the cracking furnace to be cracked into cracking oil, carbon black and combustible gas. The whole pyrolysis process is carried out in a closed environment to minimize the leakage of pollutants. The non-condensable combustible gas generated in the treatment process will be reused for heat energy utilization in the pyrolysis process after recovery. The cracked oil, carbon black and steel wire separated from the tire will be directly sold or further processed as renewable products, and then sold after increasing the added value.

Advantages of GEP waste tires recycling and disposal system

Shredding and screening integrated design, modular layout, small land occupation;

GEP intelligent control system, to achieve multi-level equipment intelligent linkage, safety production;

The core equipment adopts high precision processing, good stability and low maintenance cost;

The product line is multiple purposed, which can meet the requirements of tire coarse crushing, fine crushing, steel wire separation, granulation, grinding, etc;

The production line runs at normal temperature without any chemical additives, which will not cause secondary pollution to the environment.