Low density polyethylene, also known as high pressure polyethylene (LDPE), is the lightest variety of polyethylene resin, milky white, tasteless, odourless, non-toxic, wax-like particles with a lustreless surface. It has good flexibility, extensibility, electrical insulation, transparency, ease of processing and a certain degree of permeability. It is chemically stable and resistant to alkalis and organic solvents.

Application range of LDPE:Suitable for food packaging such as seasoning, pastry, sugar, preserves, biscuits, milk powder, tea, fish and meat pine. Packaging for pharmaceuticals such as tablets, powders, shirts, garments, knitted cotton products and chemical fibre products, etc. Packaging for daily chemical products such as laundry detergent, detergent and cosmetics. Due to the poor mechanical properties of single-layer PE film, it is usually used as the inner layer of composite packaging bags, i.e. the heat-sealable substrate of multi-layer composite films.

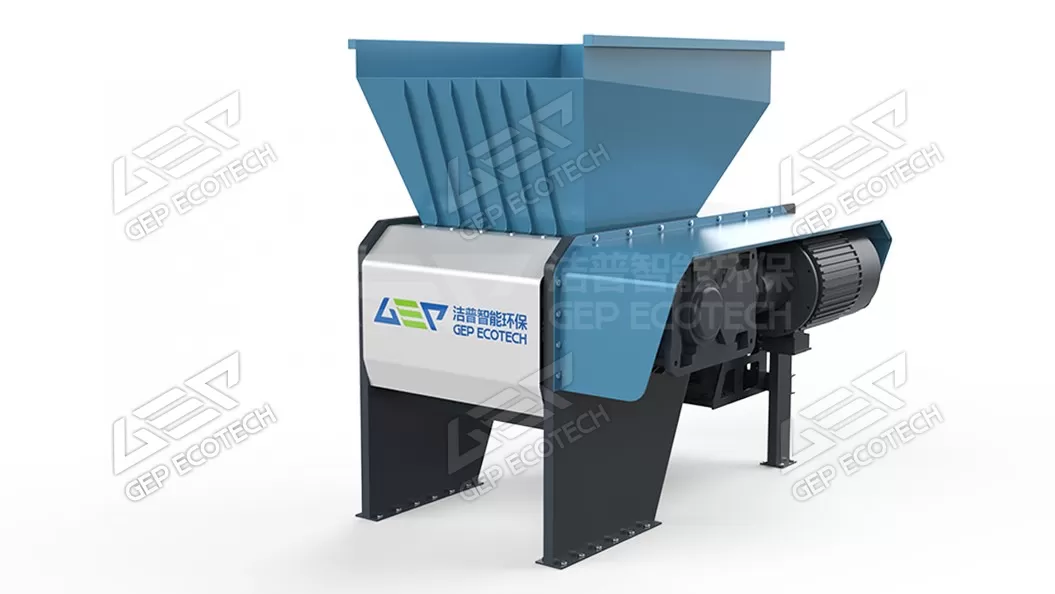

For this material, our GEP single-shaft shredders can be effective. We have three main models, GX, GE and GSD. The cutters on the spindle of the GX series move in a circular motion under the drive unit and cut each other with the fixed tooth-shaped fixed knives. The GE series adopts an oblique pushing arc pusher, which consists of two main parts: the pusher arm and the pusher body, and is driven by hydraulic pressure. labour costs and improved production continuity.

All three are equipped with the patented GEP technology for high production efficiency, stable operation and effective protection against entanglement of flexible materials.