Nowadays, people are paying more and more attention to waste recycling, treatment and reuse, and there are many common used tires around. Many people are ready to invest in waste tire recycling projects in order to make profits. However, we have to consider many issues before starting a waste tire recycling project. One of them is the selection of waste tire disposal equipment, because the selection of equipment is directly related to the efficiency of the production line, which in turn affects the profitability of the waste tire recycling project. So which treatment equipment is the ideal choice for waste tire recycling projects? Let us take a look at a waste tire recycling project in Southeast Asia.

Background introduction of waste tire recycling project in Southeast Asia

The waste tire recycling project in Southeast Asia mainly shreds car tires and truck tires. The customer purchases GEP waste tire disposal equipment, which is mainly used for the crushing pretreatment of tire cracking and oil refining and power generation. Before waste tires undergo thermal cracking treatment, they need to be crushed and steel wire separated to achieve the purpose of crushing, reducing capacity and reducing transportation costs. The waste tires will be crushed and separated by the steel wire through the GEP tire disposal production line, and then turned into rubber blocks and sent to the cracking equipment.

Introduction of Waste Tire Disposal Equipment in Southeast Asia Project

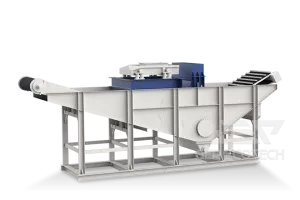

The waste tire disposal equipment of the GEP Southeast Asia project is composed of a tire wire drawing machine, a feeding chain conveyor, a biaxial shear shredder, a roller screen, and a discharge belt conveyor. The production line adopts a structural design that combines a dual-shaft shear shredder and an annular roller screen, which not only meets the requirements of output and discharge size, but also meets the planning and construction needs of customers' tire disposal, production and operation.

GEP waste tire disposal equipment has passed CE certification; equipped with intelligent monitoring equipment, it can monitor the operation status of the equipment in real time to ensure the continuity of the production line; the intelligent dust reduction equipment can operate at room temperature in real time without causing secondary pollution to the environment. It is the smart choice for tire pre-treatment.

The waste tire recycling project in Southeast Asia is just one of our project cases. GEP waste tire disposal equipment can be customized according to the actual needs of customers, and the discharge size can be controlled. The entire production line can realize automated and intelligent production. If you are interested in waste tire recycling projects and want to make considerable profits, GEP waste tire disposal equipment is your right choice!