The bulky waste problem

With the popularization of global urbanization, the acceleration of life rhythm and the increasing of life, waste treatment has become a very serious environmental problem in China and even the whole world. Among them, bulky also increased, such as waste mattresses, sofas, cabinets and so on. Such huge garbage is very difficult to transport and handle. Bulky waste shredder and solution is in big demand.

Bulky waste shredder working process

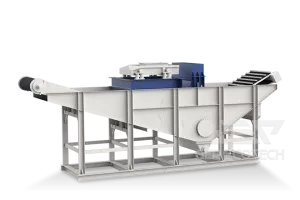

The bulky waste shredder is adopted with the double-shaft shearing type to reduce the volume and reduce the solid waste harmless treatment. The general waste sofa furniture should be first broken into small size, and then put into the boiler for incineration, so as to obtain thermal power generation. This is the need for a solid waste crusher suitable for large sofa furniture crushing. According to the material characteristics of bulky waste, GEP ECOTECH developed and manufactured the GDB series bully waste shredder, which can directly feed and discharge materials to achieve the effect of compatible reduction.

GEP bulky waste shredder

GEP bulky waste shredder is a large-scale crusher, which is specially designed for the crushing of large garbage materials. Large mattress broken mainly can be similar to the large sofa, mattress, furniture, wardrobe and other broken and reduced volume. According to the process of GEP bulky waste shredder, those discarded large pieces of garbage can be completed make value again.