Garbage classification has formed a complete chain of front-end collection, mid-end transportation and terminal disposal in various cities across the country. At present, the work of garbage sorting starts from point to point, gradually starts, and the results are obvious.

From this year onwards, cities in the prefecture-level and above will start the classification of domestic wastes. By the end of 2020, 46 key cities will basically be built into the waste sorting and treatment system. By the end of 2025, the prefecture-level and above cities will basically complete the garbage sorting and treatment system.

End treatment, precise classification

In the era of forced garbage classification, in addition to paying attention to the classification of waste sources, it also requires higher construction requirements for facilities, technologies and systems for waste end treatment. With the strong advancement of the front-end classification work, the demand for waste end processing capacity has become increasingly prominent, which has promoted the continuous enrichment and improvement of the entire garbage disposal system.

Waste sorting itself is a systematic project. It is necessary not only to do a good job of front-end supervision and education, but also to improve the loop system of end processing. All links are connected to each other to achieve a 'closed loop' to truly highlight the effect of garbage sorting. The classification and disposal and waste recycling work are the basis and premise of the whole waste sorting work, and the waste end treatment facilities are the key to forming a “closed loop”.

GEP ECOTECH believes that the end disposal of garbage is the “last mile” to break through the garbage classification. Only the end disposal link is completed, avoiding the phenomenon that “the front end is divided into categories and the back end is boiled” to ensure the classification of garbage. Each has its place to form a complete "closed loop" of garbage disposal. All provinces and cities can increase the construction and investment of waste sorting end treatment facilities, and build a domestic waste comprehensive treatment center. According to the type and characteristics of different places, the corresponding disposal processing technology is adopted to establish a sound and efficient waste end disposal system.

Recycling, turning waste into treasure

Garbage is a misplaced resource. Only scientific disposal and rational use can truly achieve profit-avoiding and avoiding waste. Regardless of social benefits or economic benefits, it is particularly important to vigorously develop the waste economy of "point waste into gold" and promote the utilization of waste resources.

GEP Smart Ring follows the principle of “recycling, reducing and harmless” domestic garbage disposal. With the research and development and innovation in solid waste treatment technology and mode, it has successfully explored large-scale garbage, waste textiles and waste tires. Domestic food waste refining solutions such as kitchen waste. Jiepu increased investment, and the combination of production, education and research promoted the development of new technologies and equipment for waste control, gradually improved the technological advancement and technological innovation level of the end-of-life disposal facilities for domestic waste, and optimized the solid waste disposal project for customers. Program.

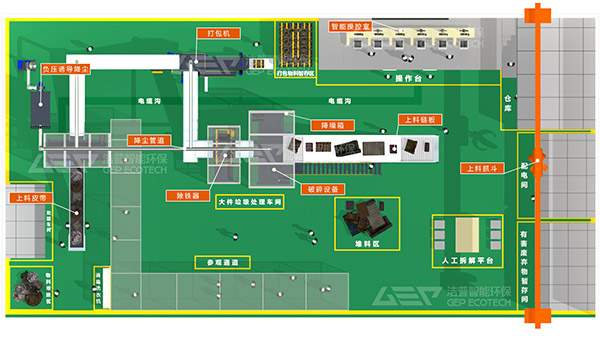

Taking the Zhengzhou Zhongyuan District Domestic Waste Sorting Center Project to be put into operation as an example, in the disposal of large-scale garbage and garden garbage, Jiepu combined with the actual situation of garbage disposal in Zhongyuan District, continuously optimized and upgraded equipment performance and disposal process, with machinery Broken instead of manual disassembly, greatly improving work efficiency and working environment, while reducing the safety hazards of crushing and dismantling. At the same time, give full play to the advantages of the original information technology, carry out bold innovation and exploration, and use the remote intelligent monitoring and production management capabilities of the GI intelligent monitoring system to effectively realize the intelligent management of the production line, and carry out remote real-time monitoring and tracking. Productivity.

In the disposal of waste textiles, GEP waste fabric disposal production line consists of in-and-out material conveying equipment, intelligent double-axis shearing crusher, GI intelligent control system and professional dust-reducing device. The equipment adopts high-wearing tools imported from Europe, which are suitable for the crushing of soft and hard materials. The anti-winding device can not only prevent the winding, but also improve the crushing efficiency, effectively overcome the problem of good toughness and easy winding of the clothes and leather fabric.

As an advocate of solid waste recycling, GEP ECOTECH has been deeply involved in the field of solid waste disposal, and strives to become a professional manufacturer and integrated service provider of excellent renewable resource processing equipment. At present, GEP has frequently obtained domestic waste disposal projects in Shanghai, Hangzhou, Jiangsu and other places, and has won unanimous praise. With the continuous strengthening of market competitiveness, GEP ECOTECH is receiving more and more attention and recognition from customers at home and abroad. At the moment, Jiepu will firmly grasp the development opportunities, optimize the quality of product supply, and develop in the direction of informationization, integration and intelligence, and “smart” will win the future.