With the deepening of the new round of technological revolution and industrial transformation, intelligent transformation is the key part to improve quality, efficiency and strength of enterprises. In order to improve the safety and reliability of the equipment and help the traditional enterprise upgrade the industry, GEP relies on the big data technology on the Internet of things, and independently develops and designs an intelligent monitoring and control system with the ability of remote intelligent monitoring and production management. It realizes "combination of management and control " on shredding production line which has the advantage of high efficiency, energy saving ability, safety and environmental friendliness.

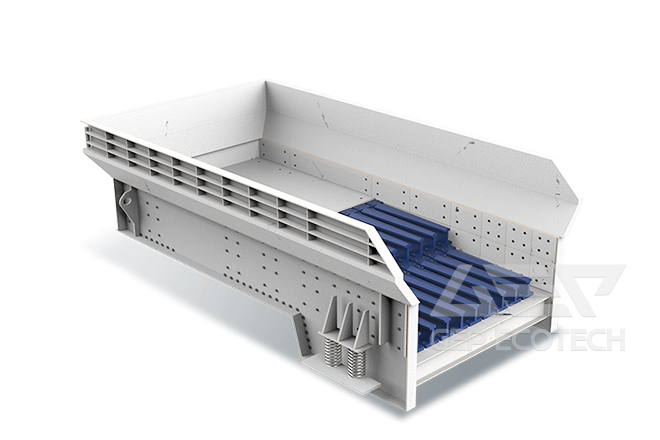

GEP intelligent monitoring system mainly consists of a single machine intelligent monitoring system and a production line with integrated intelligent control system. The single machine intelligent monitoring system is used for the intelligent monitoring and alarm of the equipment related parameters. According to the relevant parameters of different types of equipment and parameters, the relevant parameters of the equipment are collected. The related parameters of the equipment are transmitted to the control host, and the logic analysis is carried out through the PLC of the inner part of the host to realize the intelligence. Chemical monitoring and alarm output. Through the field bus or industrial Ethernet, the integrated intelligent control system connects all the single machine intelligent control systems to the intelligent control host, and makes it a whole network system. Through the PLC, the decentralized control of the equipment and the monitoring and intelligent control of the whole production line are realized.

According to the production process and quality control, GEP intelligent monitoring system can monitor and transfer the operating conditions of equipment in real time. The managers can get the overall perception of the critical parts of the shredding equipment and the overall working conditions in time. The intelligent monitoring system uses modular layout and communication, and the parameters collection and control of each device are completed by a branch station. All the communication between the single machine and the host is realized through the separate stations. On the mainframe of the monitoring system, the real-time production data of each equipment are displayed. Once a certain equipment in the production line fails, the monitoring system will alarm in time. The staff can adjust the equipment's related parameters to solve the problem of equipment failure and avoid further damage to the equipment.

GEP intelligent monitoring system combines the tearing machine equipment with the Internet / high-end intelligent technology, and provides three control modes for the customers, such as automatic control, in-situ manual control and remote operation control, so that the operation and maintenance of the production line are more intelligent and convenient. With the help of APP mobile terminal, the manager can monitor the operation of the equipment anytime and anywhere, collect and record the data of a number of devices on line and in real time, simplify the previous work of manual recording and query repeatedly, and save the manpower cost. In addition, the operation of the equipment is intuitively intellectualized and automatic feedback information in the form of data and histogram, which provides the decision support for the manager, and satisfies the monitoring and maintenance requirements of the shredding production line to the maximum extent.

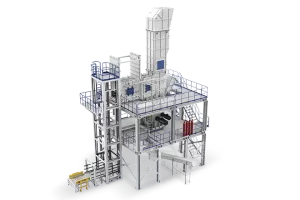

The smart factory is a new stage of the development of modern factory information. By adopting modern high technology, GEP can effectively improve the safety and reliability of the shredding equipment, save the maintenance cost, improve the production efficiency, and promote the development of the solid waste treatment plant to the direction of confidence, datamation and intelligence.