As the government has increased supervision over environmental issues, our country has attached great importance on hazardous waste and the disposal of hazardous wastes has become more and more standardized. Under the new normal condition that the requirements of environmental protection are stricter, the reduction, resource and harmless disposal have become a trend compared to the traditional disposal methods of incineration and landfill. In recent years, the voice of cement kiln cooperative dispose of hazardous wastes has been increasing.

Cement kiln cooperative disposal is a new means of waste disposal. The main principle is to use cement calcining kiln to treat solid waste and dangerous waste. At present, it can be adapted to about 60% kinds of hazardous waste and has a wide range of application. It can deal with hazardous waste, domestic waste, industrial solid waste, sludge and contaminated soil. Since 1970s, the developed countries and regions, such as Europe, America, Japan and other developed countries and regions have begun to popularize cement kiln to deal with hazardous wastes in a wide range. As of now, it has become one of the most popular mature technologies, which is of significance to both hazardous waste treatment and the development of cement industry. As of May 2017, more than 30 projects were approved by China, and more cement group began to participate. The technical route of the cement kiln dispose of the hazardous waste was formally entered into the outbreak period.

How does cement kiln cooperate with hazardous waste disposal? The cement kiln cooperative disposal is the process of harmless disposal of hazardous waste by putting the waste into cement kiln which is pretreated to meet the requirements of the kiln, and carrying out the production of cement clinker. In China, when cement kiln produces clinker, it is usually used as conventional industrial waste, such as power plant fly ash, flue gas desulphurization gypsum, phosphogypsum, coal gangue, steel slag and other general industrial wastes, which are low toxic, not easy to corrode kiln, and do not react with traditional calcium carbonate and other raw materials.

The cement kiln has high incineration temperature, long incineration time and complete disposal. It has no second treatment needs and has great acceptance ability. It is recognized as the most safe and most thorough industrial kiln in the process of treatment. In developed countries, about 2/3 of the cement plants can be disposed with the incineration disposal. Although cement kiln in China has a relatively late start in dealing with hazardous waste, it has developed rapidly. Up to September 2017, the capacity of cement kiln disposal of hazardous wastes was 1790 thousand tons.

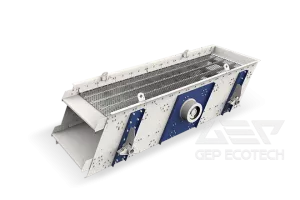

It is worth attention that the cement kiln is not a universal waste disposal plant, its processing process has strong selectivity and pertinence, otherwise it will bring many unexpected safety and quality problems, so the larger solid waste needs to be mixed and transported after the breakup of the professional garbage shredding system. GEP introduced North American solid waste shredding technology, independent research and development of intelligent shredding equipment, specially designed and optimized for this system. The shredding equipment adopts low speed, large torque and high wear-resistant cutting tools. It has large output, high efficiency and strong continuous working ability. It is well adapted to domestic garbage unclassified and with large water content. The characteristics of different types meet the requirements of shredding size of solid waste into kiln. According to the design of different cutter shapes, different torque and different crushers, a whole system of lifting, shredding, mixing and pumping is designed for the layout characteristics of the cement kiln system, and the cooperative pre treatment plan for the cement kiln is made for the customers.

From the current trend analysis, with the further development of the industry, the cement kiln collaborative disposal technology has gradually matured. In view of the disposal capacity of cement kiln, there will be 18 million tons of market space to be developed. The gap between supply and demand for hazardous waste treatment will be further expanded, and the industry will continue develop.