The 2020 Olympic Games will be held in Japan. In order to prepare for this event, the Japan Olympic Organizing Committee has collected and refined the recycled metals required for the 5,000 medals for the next Olympic and Paralympic Games, and the metal used in the gold medals. It is extracted from waste electronic equipment. The collection activities ended in March this year, and local governments received nearly 80,000 tons of donated items. In addition, Japanese telecommunications operator NTT Como stores collected 6.2 million mobile phones. A total of 32 kg of gold, 3,500 kg of silver and 2,200 kg of copper were extracted from all the collected household appliances.

On July 1, the "Regulations on the Management of Domestic Waste in Shanghai" was officially implemented, and the classification of domestic garbage became a hot topic. However, there is also a type of garbage that deserves our attention - they are called "e-waste", and discarded electronics have become the fastest-growing waste in the world. Unlike other types of garbage, the dangers of e-waste to the natural environment and the difficulty of handling it are obvious.

Waste electrical and electronic products are known as "urban mines" because of their large volume and rich in resources such as metals and plastics. Promoting the rational dismantling and dismantling of waste electrical and electronic products, effectively recycling resources, and properly disposing of hazardous wastes is a vivid practice of implementing the development concept of “innovation, coordination, green, openness, and sharing”. It is the potential to dig deep into “urban mines”. An important measure to promote recycling.

The harmful substances in electronic waste are mainly various metals. Such as lead in solder joints, cadmium in resistors/semiconductors, mercury in printed circuit boards (PCBs), chromium in metal coatings, nickel or lithium in batteries, and germanium in motherboards. In addition to metals, electronic waste can also contain harmful substances such as flame retardants, plastics and PVC, which can pollute the air when incinerated.

If we do not deal with e-waste scientifically, our body will be greatly threatened. Nervous system damage, blood system damage, kidney system damage, damage to children's brain development, kidney liver metal precipitation, respiratory diseases, etc., are all potential health threats to e-waste.

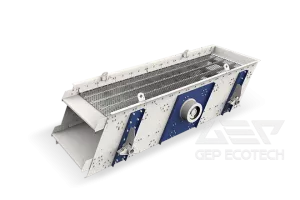

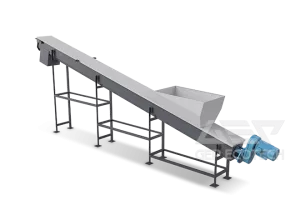

To extract precious metals from electronic products, disassembly is the first step. The electronic waste disposal production line independently designed and developed by GEP ECOTECH Intelligent Environment is mainly composed of conveying system, crushing system, sorting system, intelligent monitoring system and dust reduction system. The electronic waste disposal production line can be operated under normal temperature conditions, using environmentally-friendly and energy-saving smashing methods to disassemble and sort electronic waste. The production line runs with low noise and no pollution, simple operation, convenient maintenance, and has the advantages of purifying the environment and saving manpower and material resources. .

GEP ECOTECH electronic waste disposal production line has the function of automatic front-end decomposition. From simple disassembly to product refinement, it can be accurately decomposed, and the metal materials after crushing are sorted and disposed by magnetic separation and high-voltage electrostatic separation. Further increase the added value of electronic waste, effectively promote the recycling of resources, and effectively eliminate environmental hazards.

With the fluctuation of the price of bulk product recycling in the market, many waste electrical and electronic products processing companies choose to extend the industrial chain and deep-process the disassembled products to increase the added value of products and increase the utilization ratio of resources. The technical equipments for waste circuit board treatment, rare metal extraction and recycled plastic modification have been greatly developed. Some processing enterprises have also independently developed equipment suitable for their own production conditions through cooperation with universities and research institutes. Even some equipments have succeeded in Promotion within the industry.